Optimizing Energy Management & Efficiency in Controlled Environment Agriculture Facilities

Controlled Environment Agriculture (CEA) facilities play a crucial role in meeting the growing demand for sustainable and locally sourced food. However, these facilities have unique energy demands compared to traditional clients, necessitating a tailored energy planning and management approach. As an experienced design-build CEA general contractor, we possess substantial experience in assisting our clients in creating optimized cultivation facilities. This article will explore key considerations and strategies for managing peak loads, optimizing energy efficiency, and exploring renewable energy options in designing and constructing CEA facilities.

Understanding Your Facility Goals

Defining the type of facility and its spaces is a fundamental step in the energy planning process for CEA facilities. Unlike traditional agricultural buildings, CEA facilities encompass various areas such as cultivation, processing, packaging, storage, and warehousing. Each of these spaces has specific energy requirements and control needs. By analyzing and understanding each room type, facility managers can set energy goals and establish appropriate control strategies that lead to a comprehensive understanding of the entire building.

Analyzing Facility Spaces

A thorough analysis of the different spaces within a CEA facility is essential for effective energy planning and management. Sam Schmidt, Commissioning Specialist, ARCO/Murray said, “Understanding the operational requirements for each room type of a controlled environment agriculture facility is crucial for effective energy planning and reducing peak loads. Analyzing each room type allows project teams to set energy goals and control requirements, enabling a comprehensive understanding of the entire building to properly develop facility power requirements.” This analysis allows facility managers to identify areas where energy efficiency improvements can be made and implement load-shifting strategies. By examining the energy consumption patterns of each space, managers can determine the optimal allocation of resources and identify opportunities for energy conservation.

For example, the cultivation area might require precise environmental controls, including lighting, temperature, and humidity, to optimize plant growth. On the other hand, storage and warehousing spaces may have different energy requirements, such as maintaining specific temperatures for product preservation. By understanding the unique demands of each space, facility managers can develop tailored strategies to optimize energy usage while ensuring optimal growing conditions and product quality.

Assessing Energy Consumption

Energy consumption assessment is crucial for retrofitting existing CEA facilities and planning for new construction CEA facilities. The CEA industry lacks history and public data when compared to the commercial building industry. The Energy Information Administration (EIA) has developed a Commercial Building Energy Consumption Survey (CBECS), which provides tables to estimate energy end-use consumption including space heating, cooling, ventilation, etc. within commercial buildings. This same principle of end-use estimation is paramount in CEA facilities. For existing facilities, analyzing utility bills provides valuable insights into historical energy usage and highlights areas where efficiency improvements can be implemented. This allows facility managers to identify energy-intensive processes or equipment that may be operating inefficiently and take corrective actions.

Moreover, assessing energy consumption patterns in comparison to similar existing facilities can aid in accurately sizing energy systems for new builds. This comparative analysis enables facility managers to make informed decisions about the scale of renewable energy options, such as solar power, based on the facility’s expected energy consumption.

The PowerScore benchmarking platform from the not-for-profit Resource Innovation Institute (RII) enables standardized assessment of the energy and water efficiency performance of CEA operations. As RII builds a data set rich with crop and climate zone level data, more meaningful benchmarks can be established to guide the industry’s sustainability direction.

By understanding the energy consumption patterns and identifying potential areas for improvement, facility managers can implement energy-efficient technologies and practices, such as upgrading to energy-efficient lighting systems, staggering room schedules, optimizing HVAC systems, and adopting renewable energy solutions. These measures reduce operational costs and contribute to sustainability goals by minimizing the environmental impact of CEA facilities.

Hourly Energy Management & Load Shifting

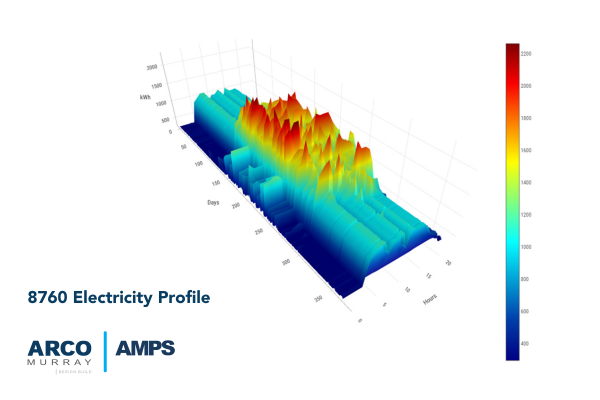

Understanding the intricacies of facility operations, including growth schedules, solar gain, temperature targets, and humidity targets, is vital. By utilizing AMPS’s (ARCO/Murray Power Solutions) proprietary energy application and analyzing the 8760 load profile on an hourly basis, load-shifting strategies can be implemented to reduce peak energy demand.

“To effectively manage energy consumption in greenhouses and cultivation facilities, it is essential to analyze facility needs on an hourly basis using the 8760 load profile. This approach allows for the development of load shifting strategies, reducing peak demand by adjusting equipment usage or schedules during off-peak hours, and helps in correctly sizing an efficient renewable energy option ” said Sultan Sabha, Project Manager, AMPS. This approach enables cost-effective energy management and minimizes strain on the electrical grid.

Strategic Energy Management Plan

Implementing a strategic energy management plan is crucial to foster a culture of conservation. Conservation programs educate and raise awareness about energy-saving practices. By developing end-use breakdowns, investments can be prioritized to maximize efficiency in areas that yield the greatest energy reduction and cost savings. This comprehensive approach ensures long-term sustainability and minimizes environmental impact.

Renewable Energy Solutions

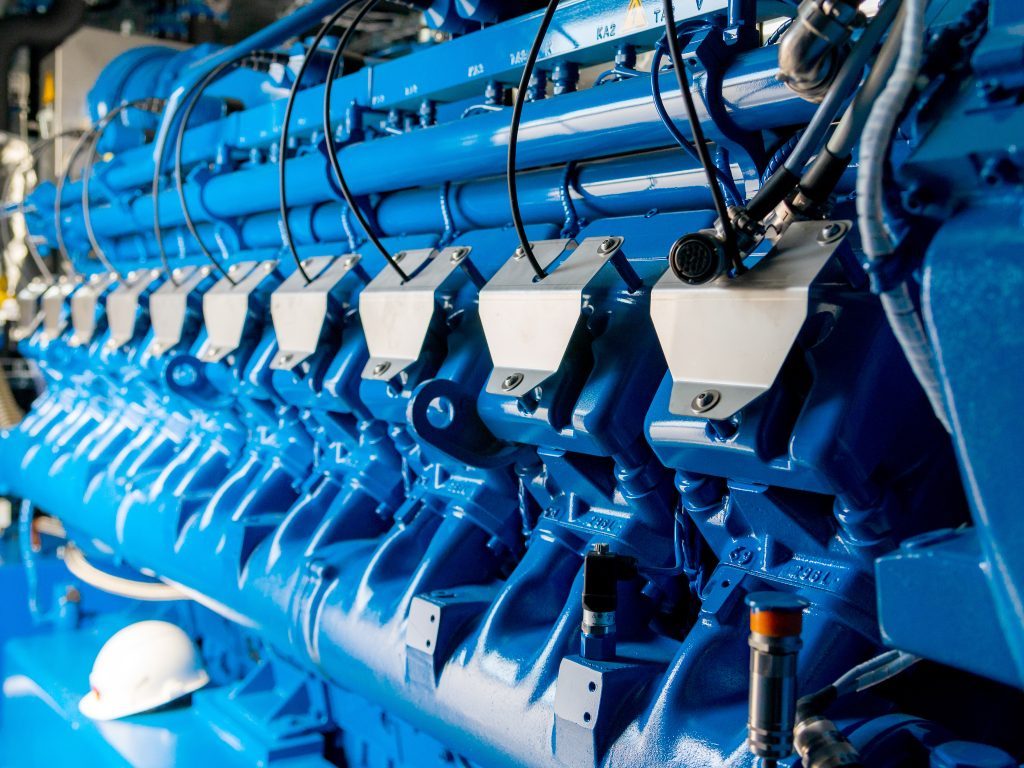

Renewable energy solutions like solar power, battery storage, and Combined Heat and Power (CHP) can also contribute to energy conservation. Planning and assessing factors like local climate, applicable incentives, and other utility programs help determine the feasibility of solar installations. With the implementation of Net Energy Metering 3.0 in California, battery storage systems become advantageous, enabling the storage of excess energy onsite, rather than sending to the grid, for use during on-peak hours. CHP systems can utilize excess heat for various functions in cultivation facilities, including heating, boilers, and CO2 recycling. Proper filtration and CO2 liquefaction may be necessary to make CO2 usable and food-grade certified.

Power Outage Solutions

CEA facilities are vulnerable to power outages, making it essential to have backup options. Generators, CHP systems, and batteries are viable solutions for power outages. The choice depends on facility goals, such as offsetting the entire facility’s power or specific critical loads. Redundancy and sizing considerations are important. Microgrids manage on-site loads and provide stability, while financial analysis helps evaluate power solutions as investments. Design builders assist in determining the most suitable option based on Return on Investment (ROI), payback period, and infrastructure requirements or upgrades.

In conclusion, as a design-build general contractor with extensive experience in CEA facility design and construction, we understand the importance of developing customized energy planning and management approaches. Implementing strategies to manage peak loads, optimize energy efficiency, explore renewable energy options, and implement power outage solutions can help CEA facilities meet their energy demands while minimizing costs and promoting sustainability.

Sam Schmidt, PE

Commissioning Specialist, ARCO/Murray

Sultan Sabha

Project Manager, AMPS

Want to learn more about our in-house power solutions or controlled environment agriculture?