Inside Mainfreight’s Sustainable Logistics Facility in Haslet, TX

The completion of Mainfreight’s 57,988 SF facility in Haslet, TX, marks a significant advancement in sustainable industrial design and construction. Through a design-build approach, Mainfreight’s new facility merges efficiency, innovation, and sustainability into one high-performing space.

Fast-Track Success

Each phase of the project—from site selection to full operation—was carefully managed to meet Mainfreight’s timeline while maintaining quality and cost efficiency. One of the biggest challenges was procuring critical electrical components, particularly the switchgear, which typically involves long lead times. By using strategic buyout methods, the team shaved four months off delivery, keeping the schedule intact. The design-build approach also streamlined decision-making and enabled tight coordination between construction and engineering, reducing redesigns and avoiding delays. As a result, the facility was fully operational just 18 months after site selection.

Sustainability at Scale

Sustainability was a priority from the outset, with a focus on energy efficiency, water conservation, and integrated automation. The facility operates at 98.5% energy efficiency, a result of carefully planned design strategies and high-performance systems.

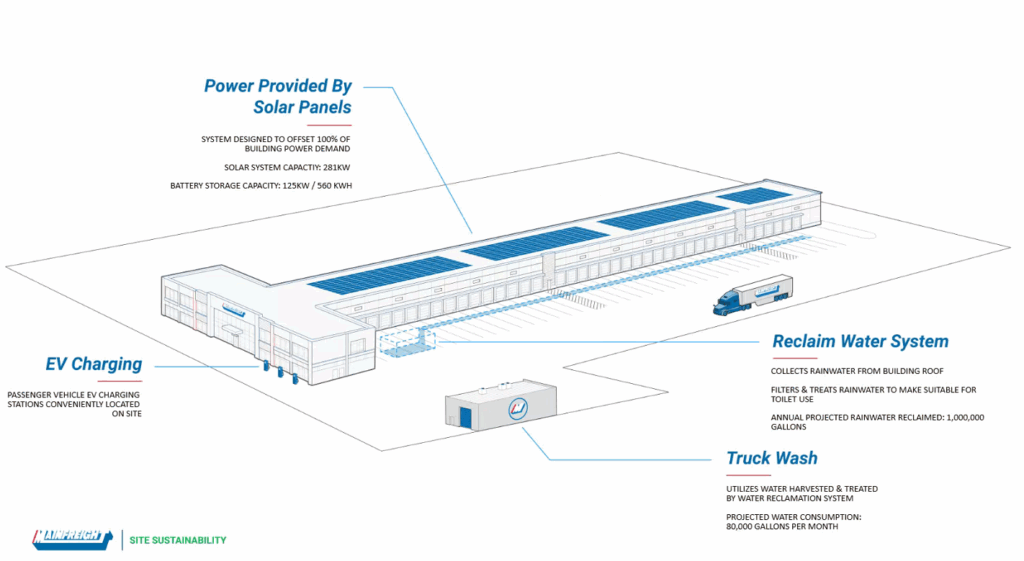

AMPS installed a 281 kW rooftop solar array and a 125 kW/560 kWh energy storage system, helping reduce reliance on the grid while ensuring stable power for operations. The system is designed to backfeed excess power to the grid, contributing to long-term energy efficiency and cost savings.

Collaborating with BLUEWTR, the facility also incorporated a rainwater reclamation system that captures runoff from the roof and repurposes it for office toilets, significantly reducing water consumption. This closed-loop system not only improves sustainability but also lowers operational costs over time.

Beyond energy and water conservation, 2nd Order Controls provided a building automation system that integrates HVAC management, energy monitoring, and safety features. The system enhances efficiency by optimizing temperature control across different zones of the facility while tracking overall energy consumption. Additionally, the duress management system ensures real-time safety monitoring at critical egress points, adding an extra layer of security for staff and operations.

Purpose-Driven Design & Innovation

Beyond operational efficiencies, the facility was designed with Mainfreight’s team and company culture in mind. A state-of-the-art commercial kitchen provides fresh, healthy meal options for employees, while a moss wall and garden space create a more inviting and natural work environment. These features reflect a growing focus in industrial design on improving the employee experience.

The facility includes a digital dashboard in the lobby that displays real-time data on energy usage, water conservation, and other key sustainability metrics. Increasing transparency while reinforcing Mainfreight’s role as a leader in environmentally responsible operations.

Mainfreight’s cross-dock facility integrates sustainable design, advanced technology, and employee-focused features to support efficient operations. Delivered through a design-build approach, it reflects current best practices in industrial construction and demonstrates how functionality and sustainability can align in a high-performance environment.