XeteX’s Holmen Facility Opens Ahead of Schedule with Tailored Design-Build Collaboration

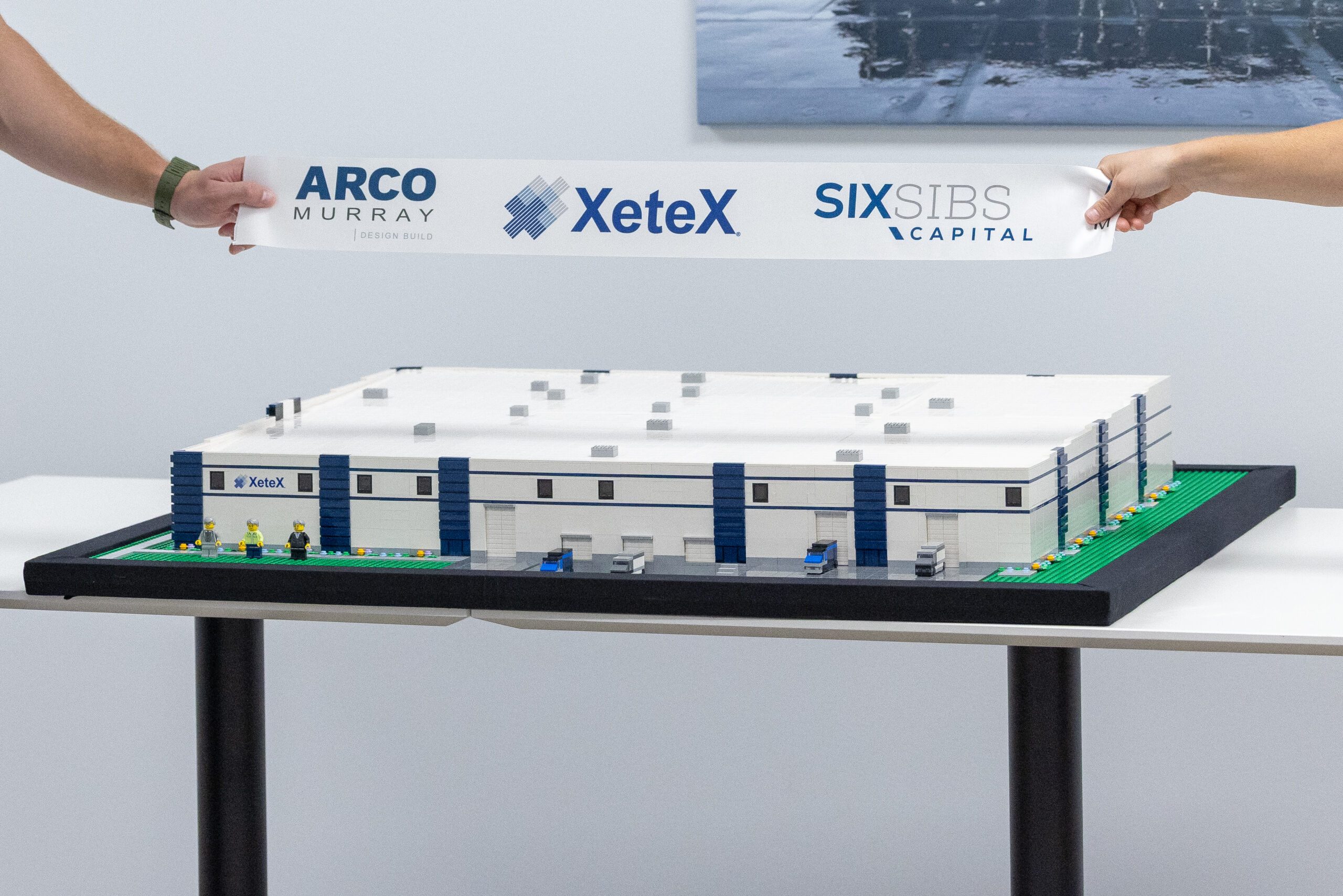

XeteX’s new 116,400 SF HVAC manufacturing and testing facility is officially open in Holmen, Wisconsin—a major milestone not just for the company’s operations, but also for the local economy and industrial growth in the Coulee Region. The ribbon-cutting ceremony brought together company leaders, city officials, and project partners to celebrate the culmination of a fast-moving and highly collaborative build-to-suit process. Designed and constructed in partnership with ARCO/Murray, the facility represents a significant expansion for XeteX, supporting increased production capacity, operational efficiency, and future innovation in HVAC technology.

But behind the scissors and ribbon was a 12-month journey of technical planning, custom engineering, and proactive problem-solving—all of which contributed to this project’s success.

Purpose-Built for Performance

From day one, ARCO/Murray worked closely with XeteX to ensure the new facility was tailored to their operations. The space consolidates manufacturing, testing, and administrative functions under one roof and includes specialized systems such as overhead cranes and 5- and 15-ton bridge cranes. Together, the teams developed a detailed equipment matrix and transfer plan to inform layout decisions, infrastructure design, and overall workflow. Weekly coordination meetings enabled quick decision-making and clear alignment throughout each phase. As construction progressed, ARCO phased the work in a way that allowed XeteX to begin moving in equipment without disrupting ongoing construction, ensuring a smooth transition from buildout to operations. The result is a facility purpose-built for performance, designed to support both day-one production and long-term growth.

Early Procurement Enabled a Faster Turnaround

With long-lead equipment posing a major risk to the schedule, ARCO proactively identified key procurement targets early in design. Large switchgear was ordered well in advance, saving five months alone. Another two months were recovered through early procurement of the utility transformer. These decisions mitigated delays and accelerated momentum. Substantial completion was reached three weeks ahead of schedule, and XeteX was able to move in two months before their original deadline.

Cost Savings Driven by Strategic Design

The design process emphasized both performance and efficiency, with ARCO’s 3D modeling, value engineering, and sample reviews brought XeteX’s vision to life while eliminating unnecessary cost. Resulting in a 20% savings within the allowance budget. Amid these technical wins, what stood out most to the client was the team’s integrity and collaborative mindset. As Philip Wood, COO of XeteX, shared:

“[ARCO/Murray] did not simply report problems—they consistently presented solutions and alternatives that balanced practicality, quality, and cost-effectiveness. In many cases, they recommended changes to our original specifications that turned out to be ‘the right thing to do.’”

A Space Built for What’s Next

XeteX’s new facility lays the foundation for long-term growth. From permitting and procurement to equipment move-in and warranty support, ARCO’s team remained focused on delivering a tailored solution that aligned with XeteX’s goals from start to finish. The facility is built not just for today’s operations, but to support the company’s continued growth in the years ahead.

Fast Facts

- 116,400 SF HVAC Manufacturing & Testing Facility

- Build-to-Suit, Ground-Up Construction

- 12 Months from Initial Design to Substantial Completion

- 3 Weeks Ahead of Schedule at Turnover

- 2 Months Early Move-In for Equipment

- 20% Savings in Allowance Budget

- 5- and 15-Ton Bridge Cranes

- Overhead Crane Systems Integrated

- Early Procurement of Large Switchgear (Saved 5 Months)

- Early Procurement of Utility Transformer (Saved 2 Months)

- Custom Layout and Equipment Matrix Developed with Client

- Tailored Power, Fuel, and Utility Infrastructure

- Phased Construction for Seamless Equipment Move-In